1. CURE DATE

OPEN UPON ARRIVAL. DO NOT LEAVE BOXED UP. LET PLAYFIELD SIT IN OPEN AIR.

Due to the swift post-production distribution of playfields to waiting customers, it is almost certain that the polyeurethane clearcoat on

your new playfield when arrived in your possession is only 2 to 3 weeks old. Therefore, the cure date for your playfield is recommended

to be 30 days after receipt. Mark your calendar, and don’t skimp on the 30 days. 45 days is even better.

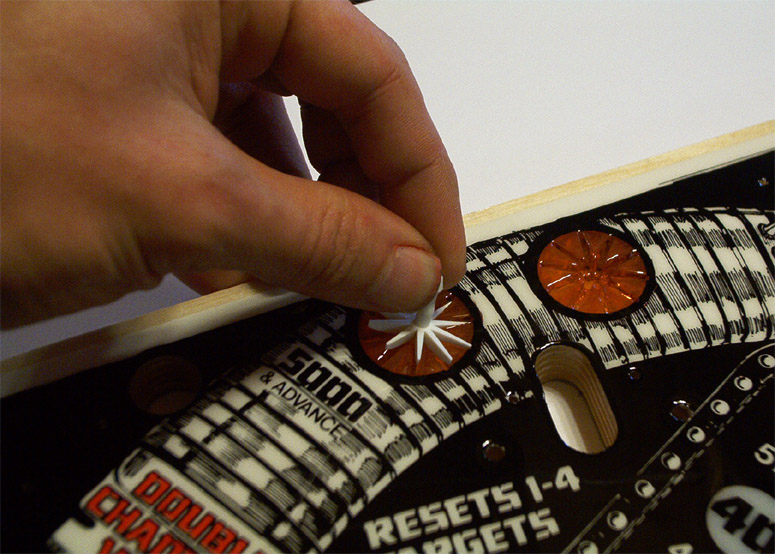

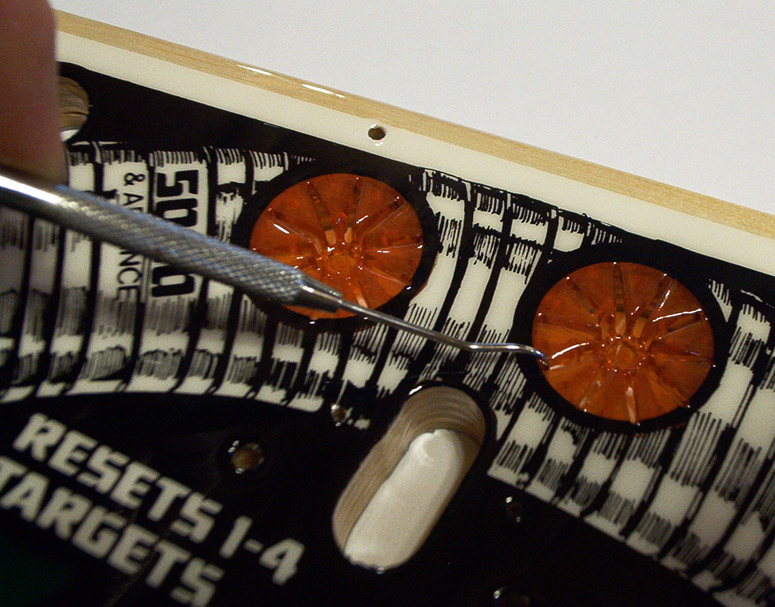

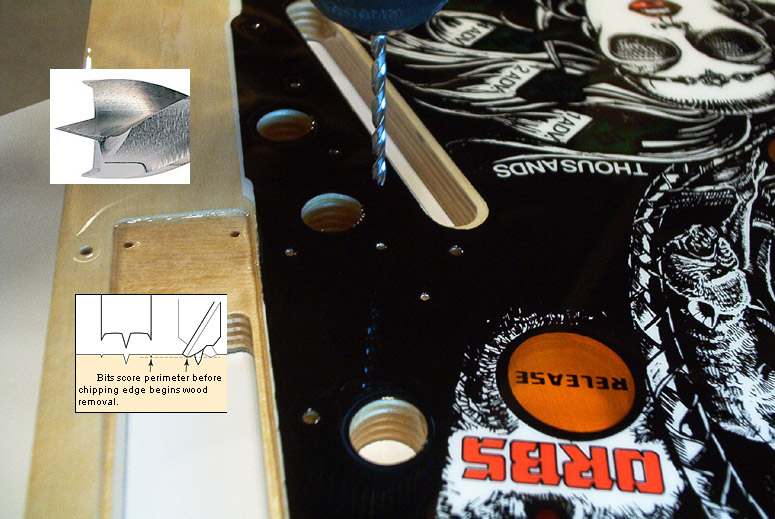

In the meantime, you CAN perform your swap before the cure date if you want. This can be a time consuming and meticulous

process, even for the experienced. So if you want to get a head start, go ahead. Completely swap, just don’t play on it.

Do NOT play a ball on the surface until after your cure date.

Do NOT wax, use Novus, Windex, etc…anything to clean or polish the surface until after your cure date.