Artwork Guidelines: Please use the following guidelines when developing your new artwork: You can work in either Photoshop CS6 (or earlier) as layers ( .psd ) or in CorelDraw ( version 19 or earlier) ( .cdr ) / Illustrator CS3 (or earlier) ( .ai ) as layers. We will not work from .jpg, .tif or .pdf files. All colors must be in RGB or Pantone PMS Colors. Note that ALL computer monitors are different and will display your graphics differently. So, what you “see” on your monitor is not necessarily what it will look like printed. The best colors to use are PMS Pantone Colors as we can color match those on our digital press.

Pasteboard: Prior to doing any Artwork, you must create your Paste Board with at least a ½” Border of Blank Space around the printed artwork area.

Scans: All Scans should be in RGB format at 100% size of Original at 300 DPI.

Resolution: If working in Photoshop then All Artwork should be created at 100% size of Original at 300 DPI.

Color: All Colors should be either RGB or PMS colors. Do not use CMYK Colors.

Bleeds:

- Plastics require a 1/8” Bleed for All Colors & White Layers beyond the Cut-Line. Cover all mounting holes with art.

- Playfield holes require a 1/8” Bleed for All Colors & the White Layers. Cover all mounting holes with art.

Laser-Cut Lines:

- All Plastics require a “Vector” based Laser-Cut Line ( .ai or .cdr only ). Photoshop cut-lines will not be accepted in “Raster” formats ( .psd, .pdf, .tif, .jpg, gif., etc will not be accepted ).

Fonts: When working in Photoshop, you Must Convert All Fonts to “Raster” layers making them a single object Prior to sending to us. When working in Vector formats you must convert all Fonts to “curves or objects” making them a single object Prior to sending to us. If you supply us with a file that contains Fonts, we will reject it.

Filters: When using Filters, you must “apply” the Filter to the layer making it a single object Prior to sending to us.

Masking: When using Masks, you must “apply” the Mask to the layer making it a single object Prior to sending to us.

There is no limit to the number of layers you create in the development of your artwork layouts. However, the final print layers must be structured as follows:

Plastics: Vector Cut-Line, Black Print Layer, Individual Color Print Layers, White Print Layer

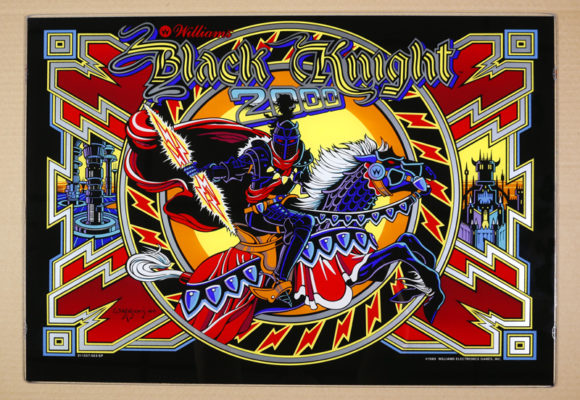

Backglasses: Mirror Print Layer ( if choosing that option ), Black Print Layer, Individual Color Print Layers, White Print Layer, Light Blocking Print Layer ( if you choose to use light blocking ).

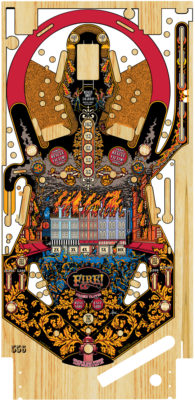

Playfields: Black Print Layer ( Architecture Layer ), Composite Color Print Layer, White Print Layer, 2nd White Print Layer *

*NOTE: The 2nd White Print Layer is specific to Inserts that are covered with graphics. The 1st White Layer has the Insert “knocked-out” of the White, while the 2nd layer of White will completely cover the insert. This is so that the Colors of your graphics are a true representation of the color as well as only 1 layer of White will allow a lamp to fully light-up the insert. If you have any questions regarding this please contact Stu at: [email protected]

Color Proofing: Customer is responsible for shipping to us a signed & dated full-size color proof print of each project being printed once they have approved all colors. Our print operator will use the customer’s approved proof print to color match all projects.